The Versatile Rock

Transforming Industries

Worldwide Lime for

Everyday Life.

Industries

Limestone is a versatile natural resource used in various industries. It's a key ingredient in cement and concrete for construction, while also serving as a flux in the steel industry, and providing raw material for agriculture, making it a crucial component for multiple sectors.

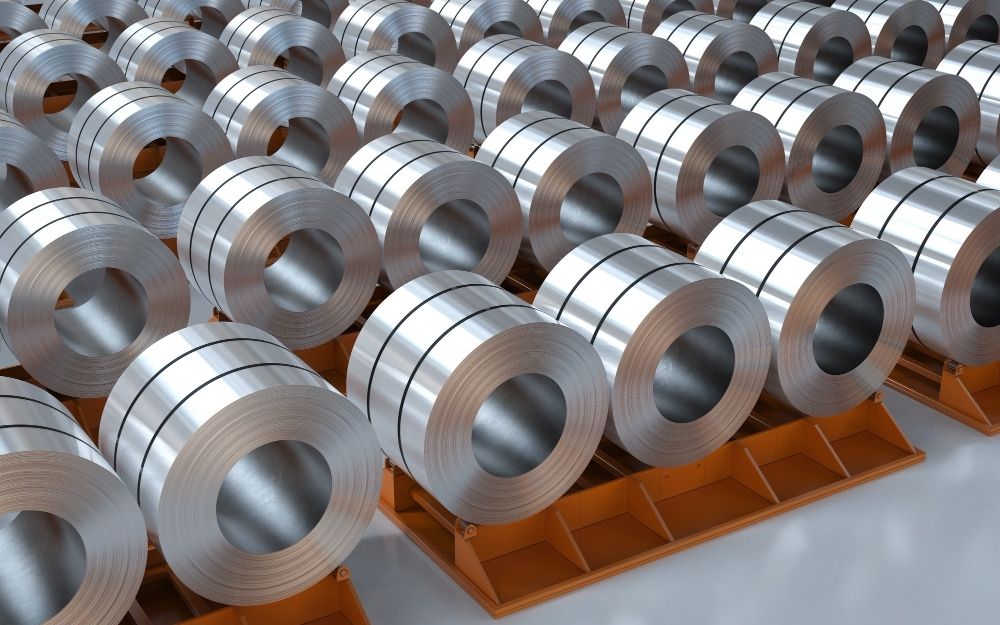

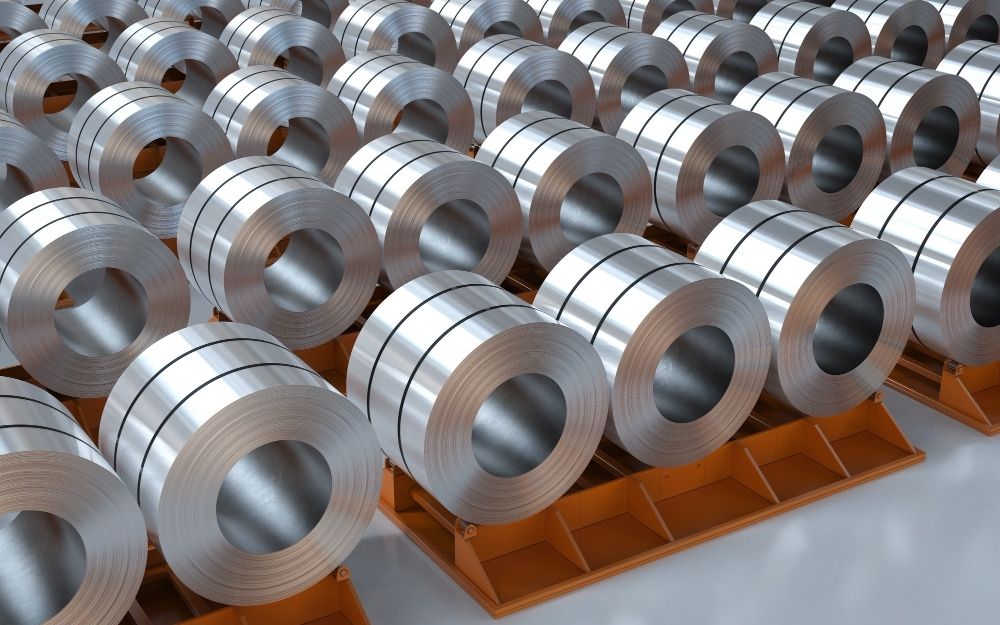

Steel Metallurgy

Our limestone serves multiple essential roles in steel production and metallurgical process . It primarily functions as a fluxing agent in the blast furnace process, aiding in the reduction of iron ore and the removal of impurities such as silica, alumina, and other non-ferrous materials. Furthermore, it plays a crucial part in desulfurization, effectively removing sulfur from the hot metal, resulting in a less brittle final product.

Limestone also acts as a neutralizing agent, regulating pH levels in the wastewater generated throughout the steel and metallurgical production process. Additionally, it serves as a refractory material due to its excellent thermal resistance, and in certain steelmaking processes, it can be used as a controlled source of carbon.

Environment

Desulfurization (FGD): Our premium-grade limestone plays a pivotal role in FGD systems, primarily aimed at mitigating the emission of sulfur dioxide removes approximately 250 tons of sulfur from the air, thereby ensuring our customers in compliance with clean air regulations for SOx, NOx, and SPM levels.

Furthermore, our limestone serves as a versatile neutralizing agent, finding application in wastewater treatment, STP, and chemical processes. It also features prominently in ecological restoration endeavors, where it is instrumental in establishing or rehabilitating natural habitats. In particular, it proves invaluable for the creation of wetlands and aquatic ecosystems that foster biodiversity.

Manufacturing Markets

The adaptability of our Signature Limestone significantly elevates product quality and performance in a wide range of industries.

In glass and fiberglass manufacturing, our high-grade limestone with specially designed PSD excels in applications like clarification, pH control, and reinforcing the strength, rigidity, and durability of products.

In the paper industry, it plays a vital role by enhancing opacity, brightness, printability, while improving optical properties, whiteness, smoothness, and controlling porosity. It also functions as a sizing and neutralizing agent during the process.

In the plastic and PVC sectors, limestone serves as a valuable filler, elevating the physical characteristics of plastic products, including stiffness, dimensional stability, and impact resistance.

Food, Pharma & Cosmetics

Our Marquee Limestone stands as a fundamental element in the formulation of food, animal feed, pharmaceuticals, and cosmetics, offering essential calcium content through various versatile applications.

In the food industry, it finds versatile uses, from refining and pH control, as seen in sugar processing.

In agriculture, it is employed to regulate soil pH levels.

In the pharmaceutical sector, it acts as an excipient for tablets and capsules, providing crucial physical attributes like binding, filling, and disintegration properties.

Within the cosmetic industry, it functions as a filler, texturizer, and absorbent, contributing to various product formulations.

Construction

Our Marquee limestone plays a multifaceted role within the construction industry.

In the realm of cement production, limestone assumes a primary position, making up approximately 95% of the clinker’s composition. Our distinctive high-grade limestone stands out as an exceptional resource, especially utilized to elevate the LSF value in clinker raw materials.

Within the mortar and adhesives sector, including tile adhesive, our limestone is employed as both a binder and filler, significantly improving workability, adhesion, and overall durability.

In the paint and polish industries, limestone serves as a white pigment extender in paint formulations, as well as a matting agent, viscosity controller, filler, and pH regulator.

Chemical Manufacturing

Our top-tier chemical-grade limestone is a pivotal feedstock in a wide spectrum of chemical manufacturing processes, facilitating the production of crucial substances like Calcium Oxide (Quicklime), Calcium Hydroxide (Slaked Lime), Calcium hypochlorite (Bleaching Powder), Calcium Sulfate Dihydrate (Gypsum), Sodium Carbonate (Soda Ash), Calcium Carbide (calcium acetylide), and Calcium Acetate (acetate of lime). These are just a selection of examples, yet the versatility of our limestone, coupled with its specially designed PSD, renders it an invaluable resource in numerous chemical manufacturing applications.

Steel Metallurgy

Our limestone serves multiple essential roles in steel production and metallurgical process . It primarily functions as a fluxing agent in the blast furnace process, aiding in the reduction of iron ore and the removal of impurities such as silica, alumina, and other non-ferrous materials. Furthermore, it plays a crucial part in desulfurization, effectively removing sulfur from the hot metal, resulting in a less brittle final product.

Limestone also acts as a neutralizing agent, regulating pH levels in the wastewater generated throughout the steel and metallurgical production process. Additionally, it serves as a refractory material due to its excellent thermal resistance, and in certain steelmaking processes, it can be used as a controlled source of carbon.

Environment

Desulfurization (FGD): Our premium-grade limestone plays a pivotal role in FGD systems, primarily aimed at mitigating the emission of sulfur dioxide removes approximately 250 tons of sulfur from the air, thereby ensuring our customers in compliance with clean air regulations for SOx, NOx, and SPM levels.

Furthermore, our limestone serves as a versatile neutralizing agent, finding application in wastewater treatment, STP, and chemical processes. It also features prominently in ecological restoration endeavors, where it is instrumental in establishing or rehabilitating natural habitats. In particular, it proves invaluable for the creation of wetlands and aquatic ecosystems that foster biodiversity.

Manufacturing Markets

The adaptability of our Signature Limestone significantly elevates product quality and performance in a wide range of industries.

In glass and fiberglass manufacturing, our high-grade limestone with specially designed PSD excels in applications like clarification, pH control, and reinforcing the strength, rigidity, and durability of products.

In the paper industry, it plays a vital role by enhancing opacity, brightness, printability, while improving optical properties, whiteness, smoothness, and controlling porosity. It also functions as a sizing and neutralizing agent during the process.

In the plastic and PVC sectors, limestone serves as a valuable filler, elevating the physical characteristics of plastic products, including stiffness, dimensional stability, and impact resistance.

Food, Pharma & Cosmetics

Our Marquee Limestone stands as a fundamental element in the formulation of food, animal feed, pharmaceuticals, and cosmetics, offering essential calcium content through various versatile applications.

In the food industry, it finds versatile uses, from refining and pH control, as seen in sugar processing.

In agriculture, it is employed to regulate soil pH levels.

In the pharmaceutical sector, it acts as an excipient for tablets and capsules, providing crucial physical attributes like binding, filling, and disintegration properties.

Within the cosmetic industry, it functions as a filler, texturizer, and absorbent, contributing to various product formulations.

Construction

Our Marquee limestone plays a multifaceted role within the construction industry.

In the realm of cement production, limestone assumes a primary position, making up approximately 95% of the clinker’s composition. Our distinctive high-grade limestone stands out as an exceptional resource, especially utilized to elevate the LSF value in clinker raw materials.

Within the mortar and adhesives sector, including tile adhesive, our limestone is employed as both a binder and filler, significantly improving workability, adhesion, and overall durability.

In the paint and polish industries, limestone serves as a white pigment extender in paint formulations, as well as a matting agent, viscosity controller, filler, and pH regulator.

Chemical Manufacturing

Our top-tier chemical-grade limestone is a pivotal feedstock in a wide spectrum of chemical manufacturing processes, facilitating the production of crucial substances like Calcium Oxide (Quicklime), Calcium Hydroxide (Slaked Lime), Calcium hypochlorite (Bleaching Powder), Calcium Sulfate Dihydrate (Gypsum), Sodium Carbonate (Soda Ash), Calcium Carbide (calcium acetylide), and Calcium Acetate (acetate of lime). These are just a selection of examples, yet the versatility of our limestone, coupled with its specially designed PSD, renders it an invaluable resource in numerous chemical manufacturing applications.